MaxEmerge 5e

MaxEmerge 5e

Curved, oddly shaped fields are no problem for the MaxEmerge 5e row unit. Electric drives allow the outer units to maintain population accuracy around curves and make the MaxEmerge 5e unit perfectly suited to variable rate planting. With these row units you’ll get: Electric drive meters that eliminate the chatter and wear typical of mechanical drives Row-by-row shutoff for perfect spacing when you’re planting around corners and curves A wide option of crop compatibility

MaxEmerge 5e

Curved, oddly shaped fields are no problem for the MaxEmerge 5e row unit. Electric drives allow the outer units to maintain population accuracy around curves and make the MaxEmerge 5e unit perfectly suited to variable rate planting. With these row units you’ll get: Electric drive meters that eliminate the chatter and wear typical of mechanical drives Row-by-row shutoff for perfect spacing when you’re planting around corners and curves A wide option of crop compatibility

Get better results out of your crops - upgrade the planter you already own

Better stands begin with improved planting accuracy: Plants have a 7% Higher Seed Survival Rate2 and 9% Higher Grain Yields1 when planted at the optimum time, depth and spacing.

With a John Deere Precision Upgrade, you get the benefits of the latest planter technology without having to replace your current planter. At the end of the day that means you can reduce your risk and…

- Achieve uniform emergence

- Plant within the optimal weather window

- Achieve uniform seed spacing

- Plant at the correct population

MaxEmerge 5e Row Unit – The most versatile option

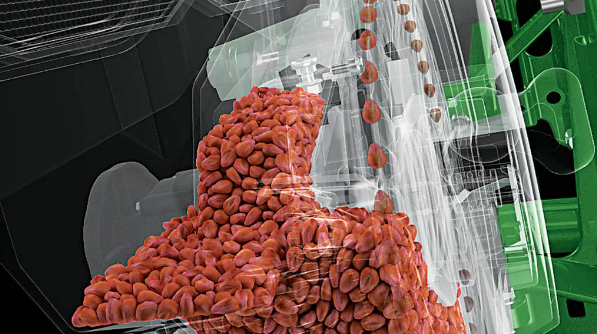

Curved, oddly-shaped fields are no problem for the MaxEmerge 5e Row Unit. Electric drives allow the outer units to maintain population accuracy around curves, and make the MaxEmerge 5e Unit perfectly suited to variable-rate planting systems. Corn and soybean growers can see overall yield potential improved by 1% - 2% thanks to more precise population and spacing.

- Electric drive meters eliminate the chatter and wear typical of mechanical drives

- Row-by-row shutoff enables perfect spacing when you’re planting around corners and curves

- A wide option of crop compatibility

Individual Row Hydraulic Downforce (IRHD) – The best system for field variability

Individual Row Hydraulic Downforce helps ensure consistent planting depth and optimal seed-to-soil contact, even in rapidly changing field conditions. IRHD adjusts downforce up to 5 times per second, and can make a 100-pound adjustment in less than 1 second…nearly 58% faster than Active Pneumatic Downforce*. Our built-in accumulator helps take shock out of your row unit, and assists with your planter overall ride. You wouldn’t drive your truck without shocks, so don’t take your planter to the field without IRHD!

- Promotes up to 9% higher grain yield potential

- Features an integrated accumulator to help protect row units from shock

- Ensures each seed is placed at the same depth

- Promotes optimal seed-to-soil contact for a picture-perfect stand

Correct Population

Electric Motors

Saving money begins with eliminating waste. Our electric drives are designed to improve population accuracy and spacing, eliminating wasteful overplanting while improving yield. Overplanting in curves and headlands results in unnecessary seed costs. The single electric drive row unit reduces this waste with individual meter control allowing for greater curve performance and individual row shutoff when crossing sections of the field already planted.

Curve Compensation

Maintain target population on curved rows within your fields. Curve compensation allows each row to receive a signal based on the speed the row unit is moving. Once the signal is received the meter and brush begin to turn at the correct RPM based on the ground speed of that respective row. This means your inside rows going slower won’t overpopulate and your outside rows going faster won’t under-populate.